Electric heating is divided into several types, each with its own pros and cons.

Central water heating

Central water heating. This type of heating is characterized by the installation of a central electric boiler and the installation of radiators in all rooms. The principle of its operation is to heat water with an electric boiler, which flows through the radiators, heating them. To achieve higher heating limits for radiators, the water can be replaced with transformer oil.

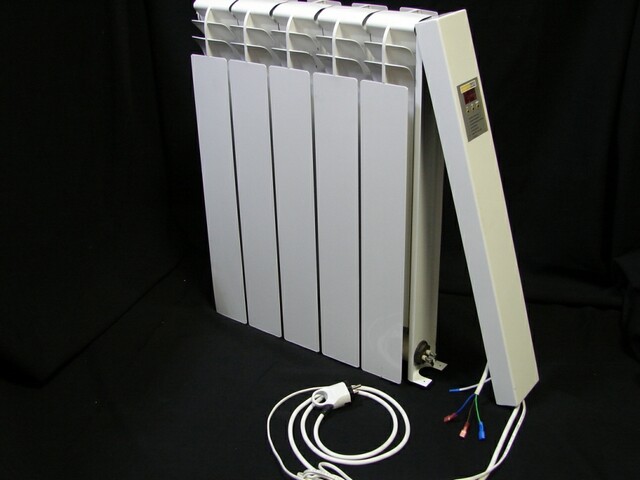

Heating on water autonomous heaters. It has a slight difference from the first method, namely: each radiator has its own electric heater that has heating control. In this case, you do not need a boiler and pipes. When choosing a water heater, give preference to a heater with a larger effective area, this gives a more efficient heating of the liquid.

Electric heaters

Electric heaters. These include different types of electric fireplaces, as well as infrared and ultraviolet heaters. These types of heaters transfer heat energy by means of radiation. Heat is felt only if you are in the zone of radiation. The air in the room is heated by the surrounding objects.

A fan heater is installed to heat the air mass in the room. Its principle of operation is that with the help of a fan, air passes through a red-hot spiral or ten. At the same time, the air heats up and, circulating around the room, carries heat.

Built-in electric heaters

Built-in electric heaters. Underfloor heating systems received a big sensation among these products. They create a feeling of warmth and comfort when in contact with the floor.

Convection heating. It consists in a simple installation of convectors in rooms, they are calculated according to their power, depending on the volume of the room. They have smooth heating control, overheating protection. For wet rooms, splash-proof types are produced. The air is heated with the help of spirals, heating elements. Convectors are safe and work unattended. The service life is 25 years.

Convection heating. It consists in a simple installation of convectors in rooms, they are calculated according to their power, depending on the volume of the room. They have smooth heating control, overheating protection. For wet rooms, splash-proof types are produced. The air is heated with the help of spirals, heating elements. Convectors are safe and work unattended. The service life is 25 years.

Electrical heating with conductive paper

Electrical heating with electrically conductive paper. This is a very interesting and simple heating option. On carbon-fiber paper, you need to stick electrode foil strips, which we connect to the mains. The heater can be glued to the wall. The size of the paper material must be chosen so that the temperature is no more than 50 ° C. This type of paper is in short supply. There is also a drawback in the fear of water of this type of heater, when it gets in, the paper quickly burns out. Various electrically conductive paper paintings are available for sale, but the price is high for heating the whole house.

Each of the options has its own advantage. You just have to decide on the choice of a suitable method of electric heating.

Making a fan heater with your own hands

The efficiency of the fan heater is very high, but the spiral dries the air and burns out oxygen, which creates a not very comfortable atmosphere. But this device will very quickly warm the air and will be indispensable in the country, as well as in the garage.

For manufacturing we need:

- galvanized sheet 0.5 mm thick;

- an electric motor with an impeller (as an option from an unnecessary vacuum cleaner);

- a spiral consisting of nichrome with a power of 1.5 kW (available on the market);

- a dense piece of slate;

- 2 circuit breakers, one 25 amp for the coil, the other for the 6 amp motor;

- electric wire with a plug;

- bolts, nuts, washers about a dozen.

We make a pipe from galvanized steel with a diameter of 200 - 250 mm, on one side we install an electric motor with an impeller, and on the other side we attach a spiral located on strips of slate. We connect the electrical wire to the motor and spiral through the appropriate circuit breakers. The fan heater is now ready for use.

A water convection electric heater consists of a container and a heating element that heats water, it is more difficult to make it with your own hands, but the circuit here is simpler than that of a fan heater.

A water convection electric heater consists of a container and a heating element that heats water, it is more difficult to make it with your own hands, but the circuit here is simpler than that of a fan heater.

- Manufacturing of containers. It is best to weld a suitable radiator from the pipes.

- Teng is easy to find on the market with built-in regulation and a trip relay.

- We will mount a heating element in the lower part of the radiator (you need to cut a thread in the radiator to screw in the heating element).

- We connect the heating element to the electrical part.

- Fill the radiator with water or oil.

The electric heater is ready for use.

Making an electric spiral at home

To make a spiral, we need a nichrome thread and an electric drill with a clamped rod 600 mm long. with a diameter of 4 mm. As you may have guessed, the thread is wound around the rod.

Connecting electric heaters to the power grid

Electric heaters are calculated by power: per square meter of the room, the power should be 100 watts. For a 4x4 meter room, the power of the heater must be at least 1.6 kW. From the above, it is clear that the total capacity of the heaters is considerable. The electrical wiring may not be able to withstand such a load, therefore, we recommend that you bring a separate wiring from the input to each heater, calculating the cross-section of the wire according to the power consumption.

It is worth considering that a heater made by a quality manufacturer will be much better than with your own hands. By making an electric heater, you gain in price, gain the most important and invaluable experience, but lose in the quality and safety of this device.