The circulation pump for the heating boiler in the system plays a rather important role - after all, it is with its help that the coolant is moved. And uniform circulation at a certain speed is a guarantee of high-quality heating of the room. Therefore, the choice of a pump for the heating system is of great importance, and in some cases an auxiliary pump for heating will be needed.

Circulation pump for heating boiler

Types of circulation pumps

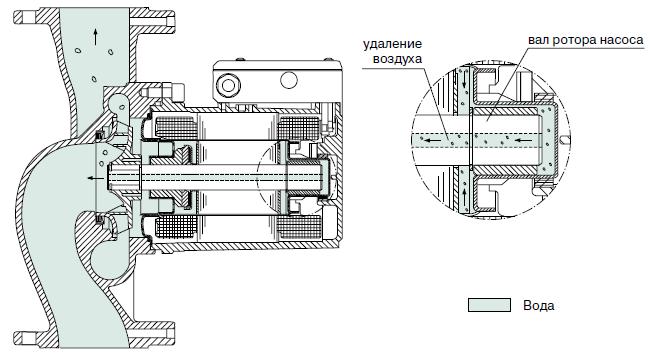

The correct operation of the circulation pump is ensured by a special element - a rotor, at the ends of which special blades are placed, with the help of which the movement of the coolant in the pipes is enhanced.

In most modern models of circulation pumps, one rotor is installed, however, in some devices, two such elements can also be found.

Regardless of the number of rotors, pumps for heating boilers will work effectively only if there is no air in the system.

There are two main types of pumps - wet rotor and dry rotor.

Glandless pump

As the name implies, in a wet rotor pump, this element is immersed directly in the coolant. The special design allows the circulating fluid to come into contact with the rotor elements and thus act as a coolant and lubricant for the individual pump elements. A clear advantage of a glandless rotor pump is that the circulation pump for central heating is practically silent, since the vibration and sound of the running rotor is absorbed by the heat carrier itself.

Mini pumps for heating of this type can be used both in heating systems and in those that are carried out in parallel with domestic hot water supply. Moreover, such a household pump for heating can be used both for residential buildings and for industrial premises (industrial circulation pump for heating). Industrial pumps for heating are powerful.

The operation of the pump is checked in two ways - visually (the back plug is unscrewed) or hardware (using a special device).

Due to the isolation of parts from moisture, a 12v circulation pump for heating with a dry rotor has a high power and can pump sufficiently large volumes of coolant, which makes it permissible to use such equipment for heating large areas. A clear difference between a dry and a wet pump, in addition to the location of the rotor relative to the coolant, is also the fact that, if necessary, in a pump with a dry rotor, it is possible to replace the motor with a more powerful one.

There is some difference between the pumps and the connection of the motor. In particular, such centrifugal pumps for heating are:

- coupling;

- flanged.

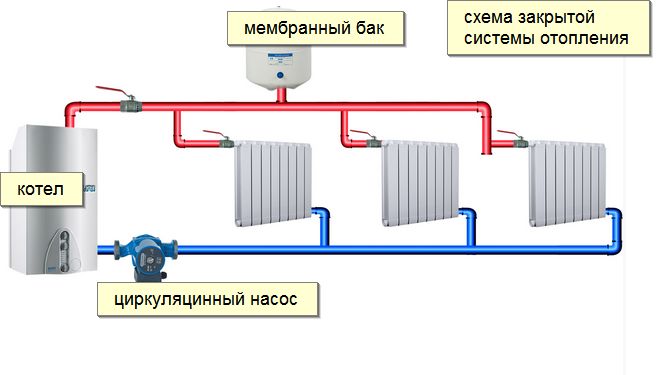

Why do you need a circulation pump

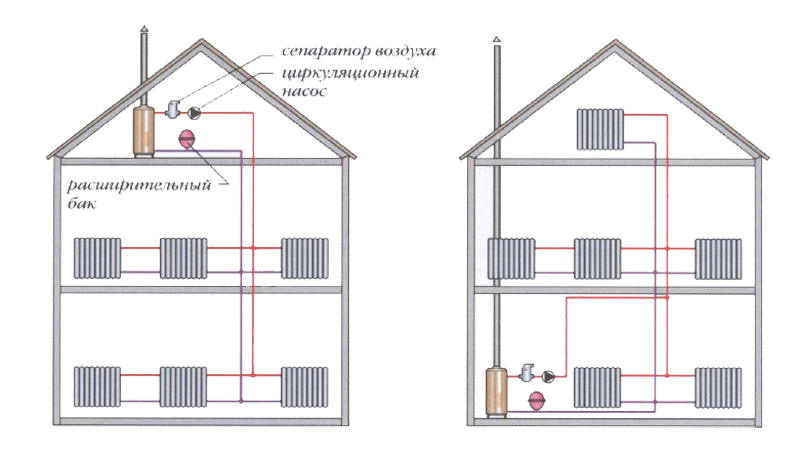

Heating systems with natural circulation of the coolant have been popular for a long time, however, even today they can be found in individual houses - there is no booster pump for heating. In such a system, the coolant moves due to the elementary laws of physics. The circulation is based on different density and mass of hot and cold heat carrier. In addition, the slight slope of the pipes of the system also facilitates movement.

However, even small errors made during the installation of the system can lead to the fact that the quality of heating the premises will be significantly lower. To prevent this from happening, the system is supplemented with a circulation pump. An electric pump for heating a house easily eliminates all the shortcomings of a system with natural circulation of the coolant. Namely:

- the system does not require a pipe slope, which is considered necessary for spontaneous movement of the coolant;

- strict rules are not put forward for the cross-section of pipes - they can have a smaller diameter;

- due to the temperature difference, plugs are not created in the system, which impede the circulation of the coolant;

- the room warms up more evenly, since the coolant moves through the pipes at a certain, always the same speed;

- the temperature difference at the inlet and outlet is minimal - flow heating pumps save a certain amount of fuel.

The stable temperature of the coolant in the system saves not only fuel, but also significantly prolongs the operation of the heating boiler. Indeed, under such conditions, the pump for pumping the heating system always works with a certain power - there are no conditions for the element to overheat.

A system in which a heating circulating mixing pump is involved is more economical.

In particular, such a system allows the use of temperature controllers. Located on each radiator, they allow you to adjust the level of its heating. Thus, you yourself can choose which temperature will be most comfortable for you. In addition, the use of such regulators somewhat reduces the level of water heating, which leads to fuel savings.