The emergence of a screwdriver as a construction tool is associated with the 16th century, even at the time of the appearance of weapons. Their flat varieties have survived to our days. Today, every home has at least one screwdriver for sure. There is no need to buy all their types, and in order to understand which version of the screwdriver is needed, it is enough to familiarize yourself with the existing varieties and their features.

You cannot do without such a tool when replacing a switch, an outlet, as well as during the repair of household devices. Many will say that instead of a screwdriver, it is better to purchase a screwdriver, however, for minor repairs, a screwdriver is usually not used, since it is easier to get a screwdriver and tighten a couple of self-tapping screws and screws when replacing the socket.

Device and principle of operation

The screwdriver design includes three main parts, which are shown in the figure.

- Screwdriver handle should provide ease of use, but there are other functions of the handle related to indication and ergonomics. Different types of tools make it possible to choose a convenient design for working in different places. For example, the handle can be short or long, hexagonal, round, or any other cross-section. The material of the handle can be wood, plastic or rubber, depending on the type and purpose of the tool. The handle can also be made in the form of a pistol or T-shaped.

- Kernel makes it possible to choose a screwdriver for specific working conditions. The available depth of the hole in which the screw or self-tapping screw is located depends on the length of the rod. But in hard-to-reach and narrow places, a too long rod will not allow the tool to work correctly, in this case a long rod can be considered a disadvantage.

- Slot type (blades) tip depends on the type of fastener to be screwed in. The names of the fasteners depend on the shape of the slot - screw, self-tapping screw, screw, etc. Previously, the most popular were screwdrivers with a straight slot in the form of a blade, since the fasteners had a corresponding groove in the head. Currently, other types of splines are increasingly used - cross, hex, Torx, sprocket, etc. An important factor is the hardness and strength of the tip, the higher these parameters, the more durable the tool will be. So that when the fastener is screwed in, the slot does not slip, a special spraying is applied to it, which makes it possible to increase the coefficient of friction.

The principle of the screwdriver is based on its design.

Operating procedure

- Insert the slot into the risks of a self-tapping screw, screw or screw.

- Screw in the fastener clockwise.

- Unscrew - counterclockwise.

- The handle may have buttons for activating various additional functions.

Views

New types of screws and self-tapping screws with different notches on the head are increasingly appearing in the retail network. Depending on this, the instrument is also being improved, and new types appear. The screwdriver was no exception. Today there is a large assortment of such tools of various designs and shapes. Many of them are used in relation to certain types of work. Consider screwdrivers, which are widely used and have become very popular in various types of work.

By the shape of the slot of the tip, screwdrivers are divided into:

- Flat, is marked with SL. The names of this screwdriver may vary: straight, flat, straight, straight. The shape of the working tip is made in the form of a flat blade and is used to work with simple screw connections. This is the most popular type of slot in everyday life for fixing household utensils or electrical work. The disadvantage of flathead screwdrivers is the inability to center the tip, which often slips out of the screw head.

- Cross, marked with PH. It has a cross-shaped cone-shaped sting, the edges of which enter the slot of the fastener of the corresponding shape. The cross-shaped grooves are located at an angle of 90 degrees to each other. Such a tool is used to connect various parts of equipment, cars, etc. The mount is highly reliable. The tapered slot allows for a significant increase in the contact surface with the head of the fastener, which is an advantage over a conventional flathead screwdriver. The impact on the screw head occurs along the four edges. The disadvantage is the high probability of damage to the splines of the screw, due to the impact on it in a narrow area.

- Cruciform with guides, marked with PZ. This profile of the slot is made in the form of two crosses, which are offset from each other by 45 degrees, for a tighter fit into the head of the fastener. This shape allows you to create additional reference faces. The additional cross is smaller in size than the main cross, and also has a shallower depth, which ensures the stability and stability of the tool in work. Phillips screwdrivers with additional notches are used when assembling furniture and other critical work. The disadvantage of this spline profile is similar to that of a conventional cross profile.

- Hexagonal(marking - HEX). This type of tool has a hexagonal tip surface that allows significantly more rotational force to be applied to the fasteners compared to cruciform tips. Such screwdrivers are most often used for electrical work. There are three types of hex screwdrivers with different tip shapes:

with internal hexagonal lug for fixing screws with a corresponding head. Disadvantage - the screw head quickly becomes unusable due to high deformation;

with external hexagonal lug on the rim, used for fastening screws with non-recessed heads, sometimes used instead of a wrench;

vibration-resistant , with a hole in the tip. This hole aligns with the corresponding ridge on the head of the fastener, which makes the screwdriver stable when working in high vibration conditions.

- Star-shaped(marking - TORX). It has the shape of a tip in the form of a six-pointed star, it is used for repairing various types of devices. Recently, this form of fasteners is gaining more and more popularity. The advantages of this type of handpieces are:

the ability to apply high torque compared to other types;

no slipping of the tip from the screw head, unlike classic flat screwdrivers;

no damage to the slot of the screw head;

increased tool life due to low radial forces, which is achieved by a special geometric shape of the spline petals.

There are different versions of star-shaped tips: « Torx plus" and " Torx»That serve for different fasteners. Outwardly, their shape is similar, but the difference is in the shape of the petals of a star - they are flattened in the "Torx plus", while in the usual Torx they are rounded. There is also vibration-proof execution of star-shaped screwdriver tips, in the center of which there is a hole for aligning it with a screw pin of a similar shape. This allows you to work in high vibration environments.

- Square... The section of the slot of the tip is made in the form of a square, has four surfaces, which are at an angle of 90 degrees to each other. The bearing surface through which the force is transmitted is small, therefore such a tool is not suitable for transmitting a large torque. In our country, such screwdrivers are not widely used, but in America they are very popular. This shape of the slot was previously common for fastening screws in vintage cars.

There are also types of screwdrivers that differ in their purpose for certain working conditions. They are equipped with special fixtures.

Flexible Shaft Screwdriver

This device is very convenient in tight working conditions. It is used in furniture assembly work and in other hard-to-reach places.

Universal screwdriver

This tool makes it possible to install different tips on the rod, which can be stored both inside the handle and in a separate case, depending on the version and the manufacturer.

Dielectric screwdriver

Such a screwdriver is used for electrical work on electrical equipment that is under voltage hazardous to humans. The handle and shaft of such a tool are covered with a special insulating material designed for a certain allowable voltage value. Most often, this value is indicated on the handle.

Ratchet screwdriver

With this ratchet device, the tool shaft can only rotate in one direction. This allows the screw to be loosened without removing the tool from its head. Using a special lever, you can change the direction of rotation.

Rechargeable

Such an electric screwdriver is similar in design. But there are some differences:

- Weight.

- Device.

- Power.

The significantly lower power of this tool is fully justified, since it does not serve for drilling a hole, and for fixing powerful screws and screws in especially strong materials, for example, in oak. This makes it possible to use a compact battery and a small electric motor. Therefore, the dimensions and weight of the tool are small.

The included electric screwdriver can also have several different tips to fit into the chuck.

Marking

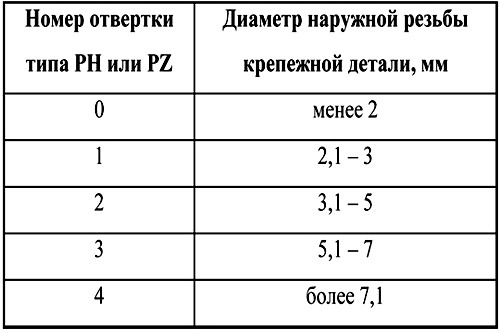

To determine the purpose and type of screwdrivers, you should be able to understand their markings. The table shows the most common tip splines and their designations. Phillips screwdrivers with different crosses have their own correspondence table, which indicates the sizes of fasteners and the tools to which they can be applied.

The following table shows the dependence of the diameter of the rods and their length on the tool number.

There is another dependence - the diameter of the external thread of the screws on the tool number:

You can also notice that some types of screwdrivers contain both letters and numbers in the designation. For example, РН 4 x 120, where РН - means a straight screwdriver, 4 - tool number, meaning the diameter of the screw, 120 - the length of the rod. The marking can include data on the material of the working part of the tool.